About Us

Steady development • innovation • value creation

Anhui Longyuan Electronics Group Co., Ltd. was founded in March 2014 with a registered capital of 20 million yuan. The company is located at the junction of the two provinces in the Yangtze River Delta-Anhui Tianchuan, focusing on the development and design of switching power supplies, integrating R & D, production and sales, and providing comprehensive power charger solutions according to customer needs. Our company has joined hands with Hefei University of Technology in Electrical Automation Engineering The school jointly develops new energy chargers. The main products are six series of new energy chargers, converters, standardized industrial power supplies, substrate AC/DC power supplies, chargers, adapters, high-power switching power supplies and linear power supplies, which are suitable for electric vehicles, lithium cars, golf carts, electric tricycles and electric tour buses. The company covers an area of 15000 ㎡, with more than 200 employees, 3 electric vehicle charger production lines, 3 SMT patch production lines and multiple automatic plug-in machines and wave soldering machines.

The company was created in 2014

The registered capital is 20 million yuan

Covering an area of 15000 ㎡

More than 200 existing employees

PRODUCTS

ProductsRecommend

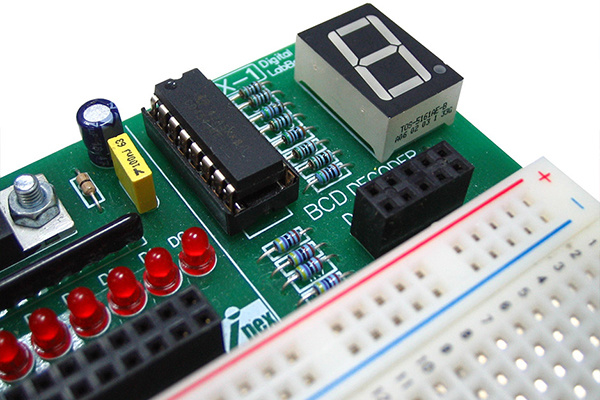

Digital Display

The main products are six series of new energy chargers, converters, standardized industrial power supplies, substrate AC/DC power supplies, chargers, adapters, high-power switching power supplies and linear power supplies, which are suitable for electric vehicles, lithium cars, golf carts, electric tricycles and electric tour buses.

Charger

The main products are six series of new energy chargers, converters, standardized industrial power supplies, substrate AC/DC power supplies, chargers, adapters, high-power switching power supplies and linear power supplies, which are suitable for electric vehicles, lithium cars, golf carts, electric tricycles and electric tour buses.

Glue filling

The main products are six series of new energy chargers, converters, standardized industrial power supplies, substrate AC/DC power supplies, chargers, adapters, high-power switching power supplies and linear power supplies, which are suitable for electric vehicles, lithium cars, golf carts, electric tricycles and electric tour buses.

New national standard

The main products are six series of new energy chargers, converters, standardized industrial power supplies, substrate AC/DC power supplies, chargers, adapters, high-power switching power supplies and linear power supplies, which are suitable for electric vehicles, lithium cars, golf carts, electric tricycles and electric tour buses.

ADVANTAGE

Our advantage

Complete qualifications

We focus on the development and design of switching power supply, integrating R & D, production and sales, and provide comprehensive power charger solutions according to customer needs.

Fully equipped

The company covers an area of 15000 ㎡, with 3 electric vehicle charger production lines, 3 SMT patch production lines and many automatic plug-in machines and wave soldering machines.

College cooperation

Our company has joined hands with the Institute of Electrical Automation Engineering of Hefei University of Technology to jointly develop new energy chargers.

Professional Team

The company has a strong management team. 60% of the elites in the team have cooperated with Canon of Japan and Samsung of South Korea for at least 4 years. Other personnel are from Panasonic Electric of Japan, and some are from Taiwan Guangbao Electronics and Foxconn Technology. They can be regarded as elite soldiers in the power supply industry.

NEWS

News Center

2023-10-26

How to adjust the voltage of electric car charger

Therefore, the transformer was carefully disassembled and the number of turns of each group of windings was recorded. The number of turns on the secondary side was 18. Because the charging voltage of the 12V battery was about 14V, the winding on the secondary side was removed for 9 turns. After reinstallation, the test found that the output voltage of the charger dropped from 27V to 12.8V. At this time, the resistance of R22 needed to be increased. After the test, the resistance of R22 was finally set at 15kΩ, no-load output of the charger is 14.2V.

2023-10-26

Principle of temperature compensation charger

The electric bicycle charger with temperature compensation function includes the basic circuits of rectifier filter, high-voltage switch, voltage conversion and constant current and constant voltage charging controller. Its characteristics are: it also includes temperature compensator circuit, which is mainly composed of temperature sensor D↓[T], inverting differential amplifier A↓[1], inverting differential amplifier A↓[2] and its bridge circuit, the temperature compensator is connected between the voltage converter of the basic circuit and the constant current and constant voltage charging controller, and is integrated into the voltage negative feedback loop of the whole circuit structure with the output voltage of the basic circuit amplifier.

2023-10-26

The working principle of electric car charger

220v AC is filtered by T0 bidirectional filter to suppress interference, D1 is rectified into pulsating DC, and then filtered by C11 to form a stable DC of about 300V. U1 is a TL3842 pulse width modulation integrated circuit. Its 5 pins are the negative pole of the power supply, 7 pins are the positive pole of the power supply, and 6 pins are pulse output to directly drive FET Q1(K1358). The 3 pins are limited by a large current. Adjusting the resistance value of R25(2.5 ohms) can adjust the large current of the charger.

PARTNERS

Cooperation Partner

Racing pigeon

Auspicious lion

Xinlei

Little Camel

Zongshen

Lexing

Beit

Focus on the development and design of switching power supply

WeChat QR Code

Telephone:180 9831 3868

Telephone:158 5500 5388

Address: No.4 Zhenglong Road, Qinlan Town, Tianchang City, Chuzhou City, Anhui Province

Mailbox:397708178@qq.com

Copyright: Anhui Longyuan Electronics Group Co., Ltd. | Business License